In Win Mod in Taiwan - Day 2 Summary

The first day saw many teams cutting and chopping up their cases, but on day two the heat was definitely on in the In Win factory as the eight teams battled with some high temperatures. With 16 hours of modding left, it was time to nail the more extensive work and start fitting the water-cooling systems provided by EKWB and Bitspower.Click to enlarge

Click to enlarge

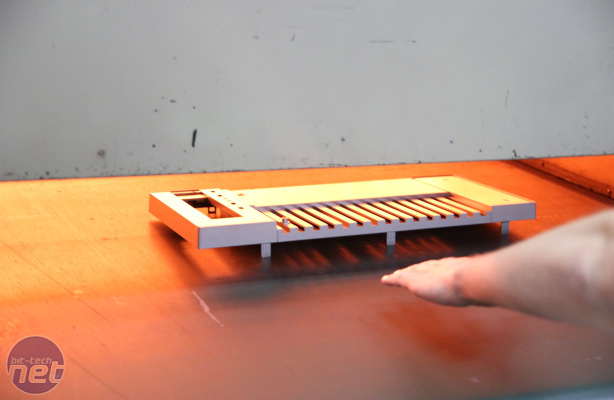

First up is the UK team - Dave Alcock and Daniel Harper. They were amongst the first to use In Win's professional spraying facilities on the top floor of the factory, but had to deal with curing ovens raising the already toasty temperatures even further. Once the front panel had been sprayed, the ovens were used to help the paint dry a little quicker, with waterfalls at the edges of the room to catch dust and paint particles.

Click to enlarge

Click to enlarge

The heat here was excessive, largely due to the ovens, and several teams had problems getting good finishes too. Dealing with more than one section meant spending several hours in here - the modders had some tough working conditions.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.